May the Drawbar Force Be With You

As important as a rigid tool-to-toolholder interface is for optimum machining so too is the clamping force of a machine tool’s spindle drawbar on the toolholder. Many times overlooked or neglected until it’s too late, drawbar pull-force performance should be checked...

Are Shops Shying Away from Shrinkfit?

We, as a global tooling supplier, interact with countless numbers of shops on a daily basis, and lately, many of them have voiced growing concerns centered around safety. These concerns stem from the fact that in tight labor markets, they are forced to hire lesser...

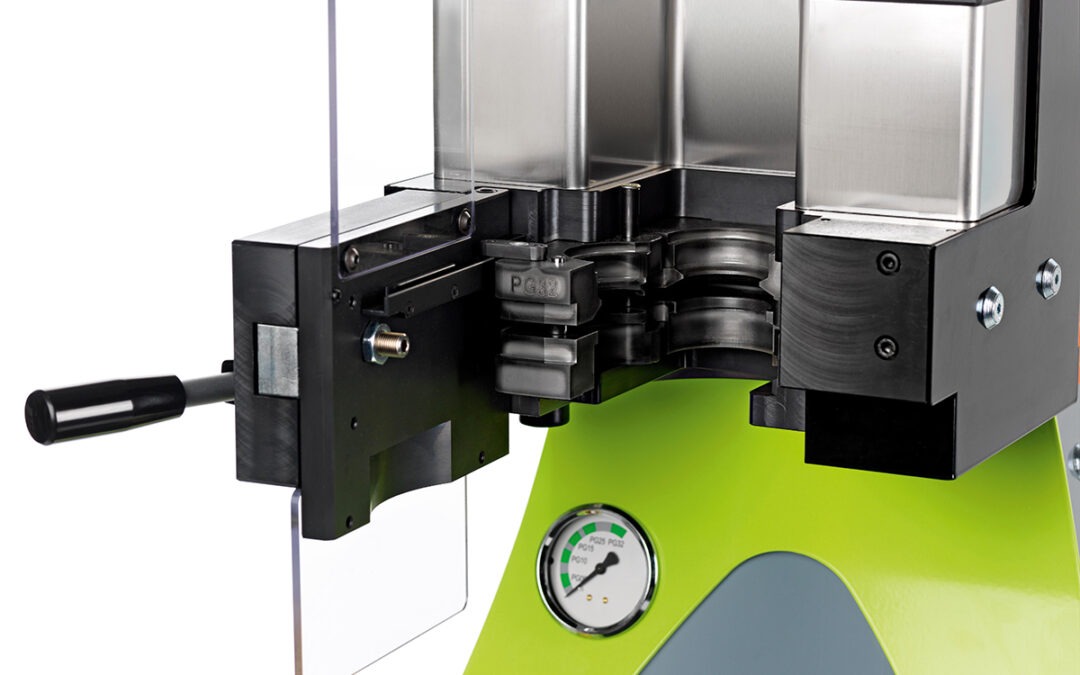

New Single powRgrip Unit Packs a Multitude of Benefits

Like the other members of the powRgrip family of toolholding systems, the new powRgrip Single is easy to use and provides fast, efficient and safe operation. It’s also smaller in size and manufactured with Swiss precision that ensures strong and stable gripping for...

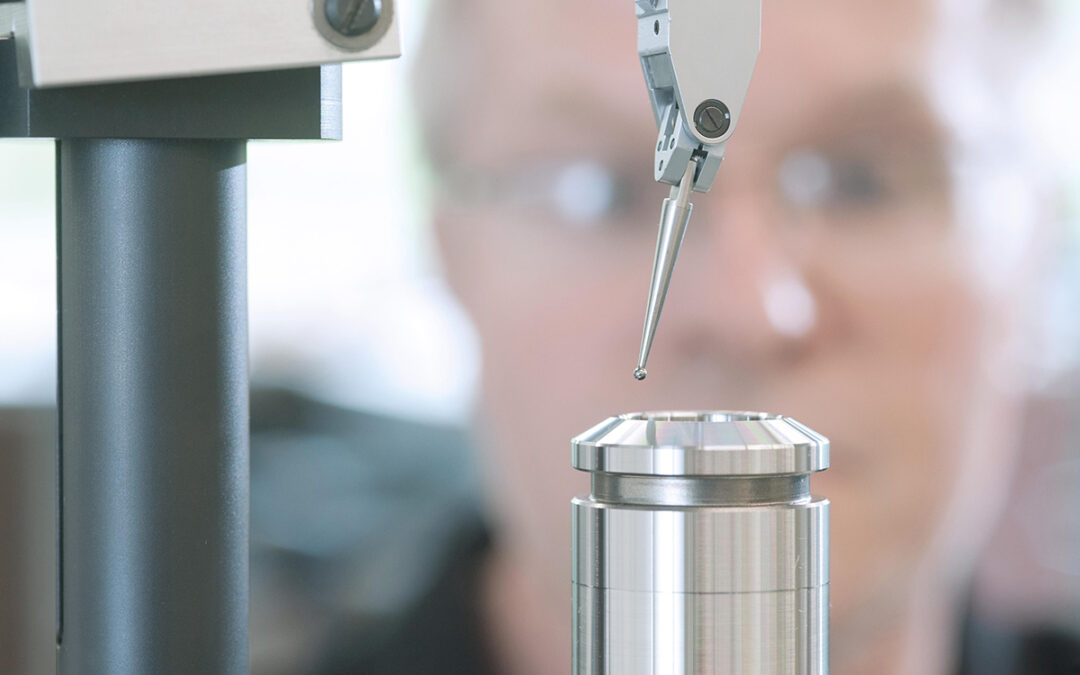

5 Ways We Live Up to Swiss Machining Precision

If your work requires part tolerances that are measured in nanometers and you turn to Swiss machining to get the job done, when you say you need the highest “precision” you mean it. If you are like us, you might even get annoyed when someone else uses the word...

A Little Bit Of Coolant Goes A Long Way

Because of economic and environmental issues, an increasing number of manufacturers are gravitating towards minimal quantity lubrication (MQL) in their metalcutting operations. MQL does not require the complex circulation, filtration and testing systems required with...

Get an Edge On Better Machine Setups

Determining edge and feature locations of a workpiece is critical to proper machine setup. In fact, little else matters in terms of machining parameters if the cutting tool doesn’t know exactly where to start. In a best-case scenario, the result might be an...

Time to Change Your Toolholders If You Consider Them Consumables

Because some toolholding systems have very limited working life cycles, many shops consider them consumables, a mindset that translates into increased job costs. Additionally, such systems are too involved and require significant user training to avoid accidents as...

Try Before You Buy

While some tooling suppliers may claim to, few, if any really allow shops to try tooling before they buy. REGO-FIX, on the other hand, keeps a demo inventory of tool holders in stock specifically for that purpose. On top of that, the company provides an ROI form that...

What’s With All the Chatter?

Depending on the application and part, setting up machines and tools for a job can be a lengthy, complicated process. Machine speeds and feeds, axial and radial cut depths and tool setups must all be optimized for maximum efficiency and productivity, and the process...

Swiss Engineering: The Epitome of Precision

Switzerland’s reputation for blue-ribbon engineering is as pervasive as its prominence for precision time pieces and fine chocolate. It’s more than a generally held belief. What drives those accomplishments is ingrained in Swiss thinking; it’s an aspect of the people....

Machining Memos isn’t just about REGO-FIX – it’s about what your shop needs to achieve manufacturing success, from how to handle runout and master high-speed machining to what things like blockchain technology or ergonomics have to do with your part-production operations.

Latest News:

REGO-FIX Aligns Leadership with Company Growth

WHITESTOWN, Ind., January 6, 2025 – With the recent expansion and opening of its Center for Machining Excellence, manufacturer of Swiss-precision tooling technologies REGO-FIX has aligned its leadership team with the continued growth of the company’s North America...