powRgrip

Redefine Toolholding Security, Convenience and Precision with REGO-FIX powRgripWHEN YOU’RE READY FOR REAL PRECISION

No fumes. No heat. No hassle. With tool changeouts in under 10 seconds and TIR of under 3 µm, powRgrip handles everything from high-speed milling and drilling to coolant-free cutting.

- TIR of <0.0001 (≤3 µm) and length adjustment repeatability of <0.0004″ (10 µm)

- Reduced vibration for longer cutter life and lower overall tooling costs

- 1,100 Nm of clamping torque

- Z-level adjustment repeatability within 10 µm

- 5-year/20,000-cycle warranty

- Drill, ream, tap and mill – both roughing and finishing operations

Want to try it in your shop?

Simple toolsetting in under 10 seconds

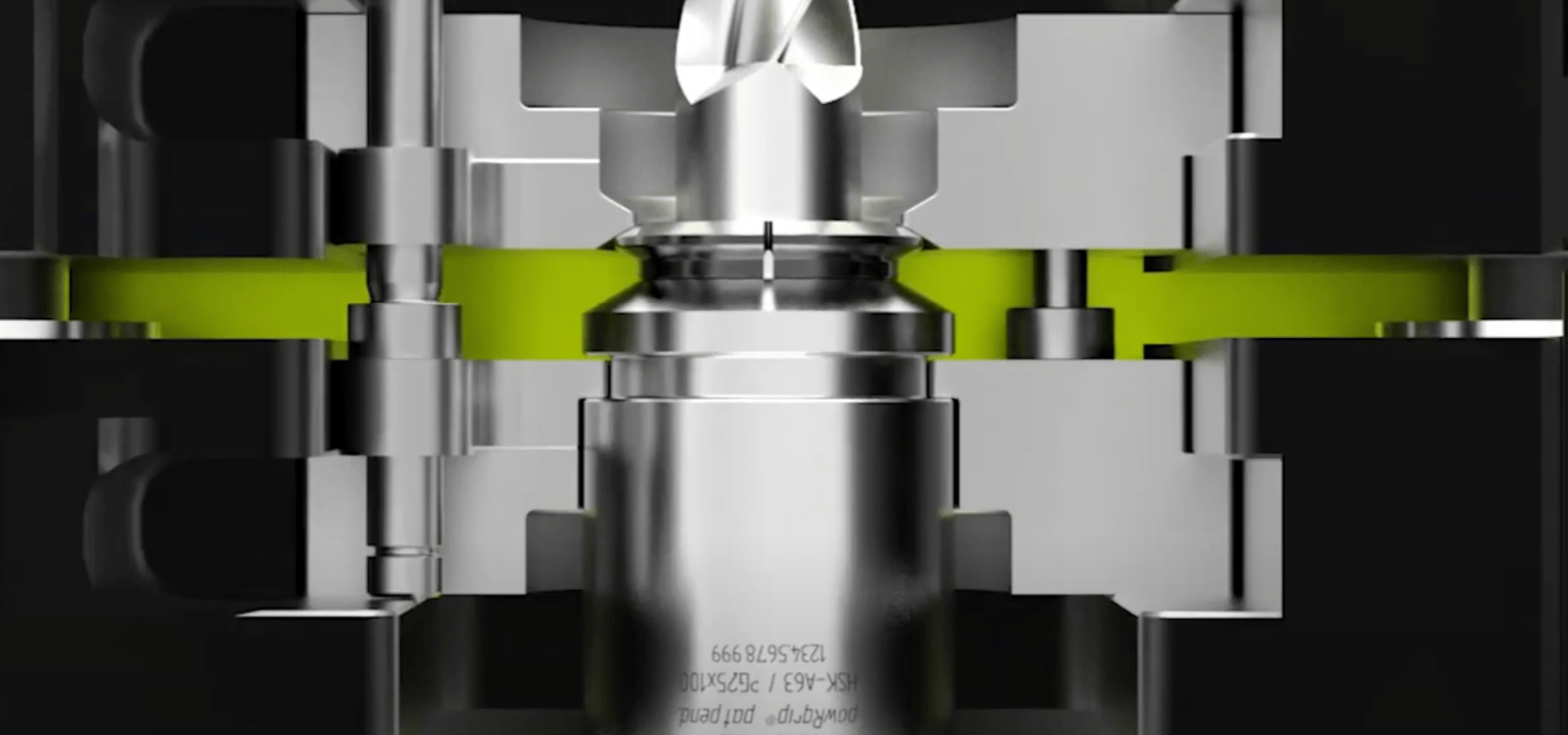

Tabletop powRgrip toolsetting units use a hydraulic press to insert special shallow-tapered collets into holders with a matching taper. Automated and manual options available.

- Tool changeouts in under 10 seconds

- Handle and use tools as soon as they’re loaded

- Interchanges collets from tool shank diameters of ø0.0079″–1.0″ (0.2 – 25 mm)

- Handles tapers including CAT, HSK, BT, CAPTO, BIG +, TC and ISO

- High vibration damping through a unique interrupted-surface design

- Clamps carbide or HSS in h6 tolerance, including Weldon flat

- 5-year (PGU 9500) or 2-year warranty

- Powered toolsetting units run on standard 110V AC

Key Product Features

Reduce tooling inventory with one system for all types of tool shanks and materials in h6 tolerance and sizes from ø0.0079″ to 1.0″ (0.2 to 24.4 mm).

Industry-leading 1,100 Nm clamping torque rating.

“Z” length adjustment repeatability of <0.0004″ (10 μm).

No toolsetting heat, chemicals, fumes or injury risks for complete worker safety and long tool life.

Superior clamping force, vibration damping and precision with toolholder-to-collet and collet-to-tool shank interfaces

5-year/20,000-cycle warranty: A properly maintained powRgrip holder and collet will maintain TIR ≤0.0001″ with no erosion of impregnated surface treatment.

powRgrip Products

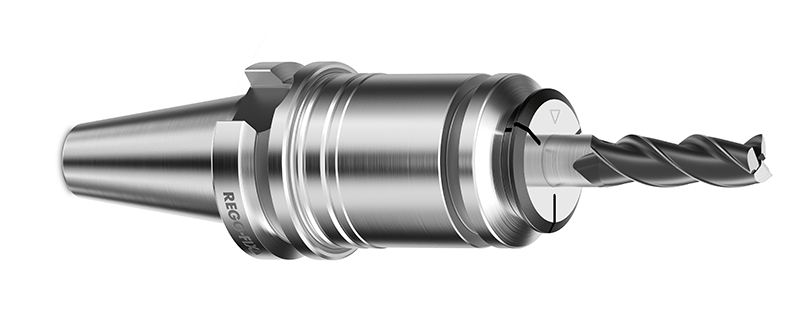

PG toolholders

Minimize runout – boost productivity

PG collets

Standard, coolant-flush, long, microbore, short, turning and tapping, all with Swiss quality

secuRgrip® for powRgrip

Form-fit for 100% pullout protection

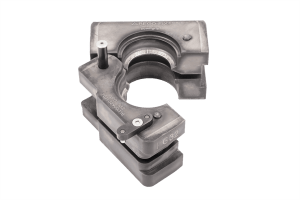

Clamping units

Automatic, automated and hand-pumped manual models

Clamping inserts

For PG 6/PG 10/PG 15/PG 25 collets and PG 6/PG 10/PG 15/PG 25/PG 32 collets

powRgrip special solutions and accessories

Balancing, presetting, storage, cleaning and coolant options along with wrenches, bars and screw drivers