REGO-FIX: ER

Better toolholding, better parts, better tool lifeOUR BEST IS YOUR BEST

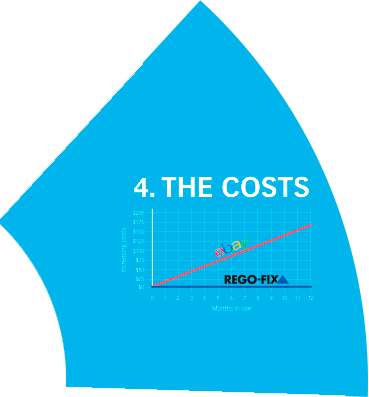

When is a bargain collet no longer a bargain? When its flaws limit its performance – and your tool life. Start with the industry’s best and achieve the results you deserve.

- Industry-leading product range from 0.008″- 1.417″ (0.2 mm-36 mm)

- Factory-balanced BT, CAT, SK, HSK, CAPTO, cylindrical-shank, ISO 20 Morse taper and automotive-shank toolholders, plus tapping toolholders for direct thread cutting

- 16-slot design and high vibration damping for TIR of <0.0004″ (10 µm, Standard Precision) and ≤0.0002″ (5 µm, Ultra Precision)

- Up to 20% more clamping length in smaller diameters

- Self-locking Hi-Q ER nuts for better clamping force and balance with less chance of improper assembly

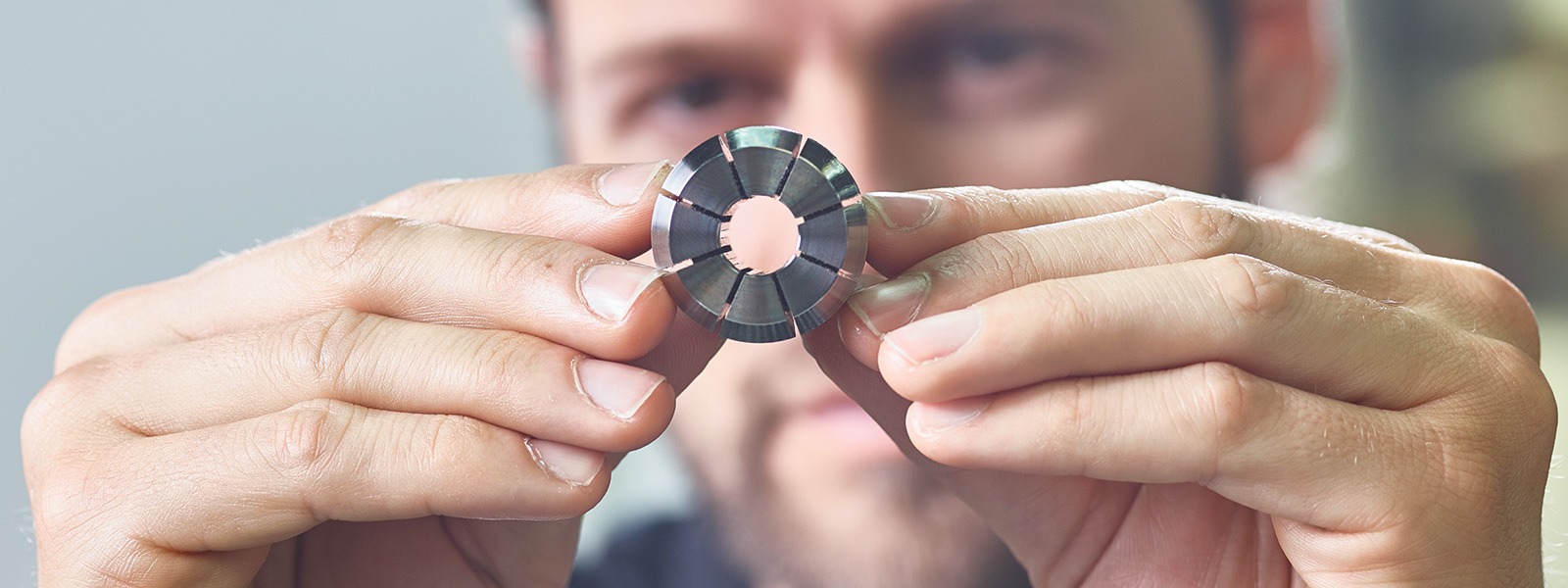

ER Collet Comparison

Click on a pie for more information

Key Product Features

3-point measurement of all AT3 steep tapers, exceeding the common 2-point system

Controlled toolholder thread runout for more-accurate alignment with the collet nut

Full lot traceability of all toolholders for maximum reliability and process control

Tighter thread tolerances for reduced friction with greater holding torque and lower TIR

All toolholders 100% precision balanced for use at the highest rpm ratings

Modified pull stud thread design to eliminate steep taper growth from pull-stud assembly

ER Products

ER floating chucks

Standard ER

Robust performance for many applications.

Ultra-precision wide

High performance results

Rigid tapping

Available for multiple standards

Microbore

For micro-machining

secuRgrip form-fit

For heavy machining

Metallic sealed

For internal cooling, threaded inserts and ER collet reductions

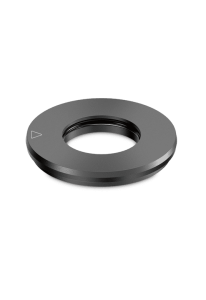

ER clamping nuts

Standard and Hi-Q for high torque and excellent balance

ER special solutions and accessories

Tool assembly assistant, plus tools, balancing, storage, cleaning and coolant options