Today’s RFID Technology Isn’t a Chip Off the Old Block

Radio-frequency identification (RFID) chip technology has saved many a production run simply by keeping track of and managing tools and toolholders. With the advent of Industry 3.0, toolholder embedded RFID technology expanded beyond what was essentially a license...

REGO-FIX Sets the Bar for Sustainable Manufacturing

Long before it became a global initiative, REGO-FIX championed energy efficient, sustainable manufacturing. In addition to utilizing sustainable designs and approaches in its own production operations, the company provides its customers with a broad range of...

Tool Management Is More Critical to Your Bottom Line Than You Think

Whether you’re a small five-person shop, a large manufacturing company with multiple facilities or somewhere in between, all the aspects of your production processes can affect your bottom line – and that includes tool management. Larger processes such as CNC...

Premature Tool Wear Is Often Due to the Compound Nature of TIR

Though oftentimes measured in millionths of an inch, total indicator runout (TIR) or simply runout is among the top concerns of every machining operation – especially those requiring tight tolerances. Though not always fatal to a particular machining process, TIR can...

Personal Preferences and Applications Drive Spindle Interface Choice

Now days, it seems every shop has its own preferences when it comes to types of machine spindle interfaces, and among those, the most common are steep taper CAT, HSK and CAPTO type interfaces. While each has its own benefits and shortcomings, all fulfill specific...

Do You Know Where Your Tools Are?

Manufacturers and shops are constantly searching for greater production efficiencies that, in turn, lead to greater profitability. Shortening cycle times, faster tool changes that minimize machine downtime and automation are all avenues to cost-effective production,...

Get a Grip on Heat and Chatter

As any machinist knows, a number of critical factors need to be controlled or eliminated to avoid detrimental situations during a production run. Heat buildup and vibration, for instance, are two of the most important elements to limit and regulate given that they’re...

Tooling Customized for Success

For the last four years, REGO-FIX has steadily invested in growing its Technology Lab to maintain a commitment to industry-leading customer support. Today, the REGO-FIX Tech Team is instrumental in making sure customers have exactly what they need when they need it...

REGO-FIX Triangle of Core Values Extends Beyond the Company Walls

The REGO-FIX Triangle of Core Values existed decades before the advent of corporate philosophies and mission statements. Those values were, in fact, personified in company founder Fritz Weber. Story has it that way back in the company’s beginnings, Weber’s bank made...

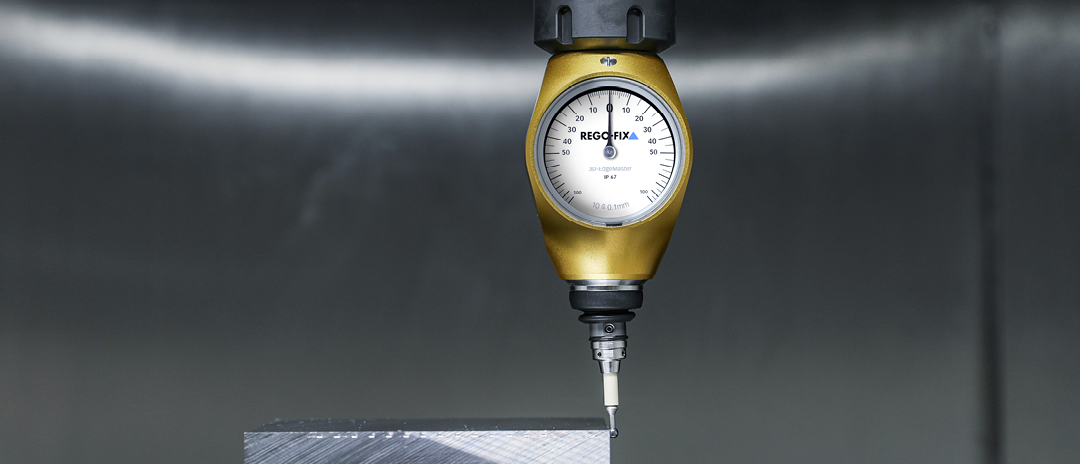

Optimizing Machining System Accuracy

A manufacturing shop can apply the best machine tools, toolholders and cutting tools, but bad parts or even machine crashes may result if the workpiece setup is not accurate. Every element in a machining system is important for success. Precisely establishing...

Machining Memos isn’t just about REGO-FIX – it’s about what your shop needs to achieve manufacturing success, from how to handle runout and master high-speed machining to what things like blockchain technology or ergonomics have to do with your part-production operations.

Lastest News:

REGO-FIX Announces New Center for Machining Excellence in Indiana

Whitestown, Ind., October 24, 2023 – Focusing on “Productivity through Partnership,” Swiss tooling manufacturer REGO-FIX, inventor of the standard-setting ER collet, has announced plans to build a state-of-the-art technical hub for the machining industry at its North...