Education and Innovation Through Partnerships

When it comes to optimizing part machining processes, it takes an entire village from start to finish. Excellence in high-quality manufacturing is only achieved through collaboration, learning and the development of new ideas. With insights from Zach Doleh, REGO-FIX’s...

Chances Are You’re Not Getting the Most from Your Tools

There was a time when cutting tools had the potential to outperform the machines that ran them. However, advances in machine technology that provide higher speeds, greater precision and repeatability along with software developments to program high-efficiency...

Deep Part Features Call for an Extra Boost of Coolant

When it comes to machining deep part features, the long milling cutters used to reach them often need a bit more cooling capability beyond just standard flood type. In these situations, shops can give their flood coolant an extra boost with REGO-FIX CoolBore and...

An Abundance of Excellence in 2024

While much of the industry is focused on IMTS 2024, we have to admit that we’re equally excited about the completion of our Center for Machining Excellence. Opening in October, this facility is co-located with the REGO-FIX North American headquarters. Through...

High Speed Machining Calls for High-performance Tooling

In the aerospace industry, especially when it comes to commercial aircraft manufacturing, speed is critical because the faster parts are machined, the more planes are produced. So, if these manufacturers know of a tool holding system that allows them to triple their...

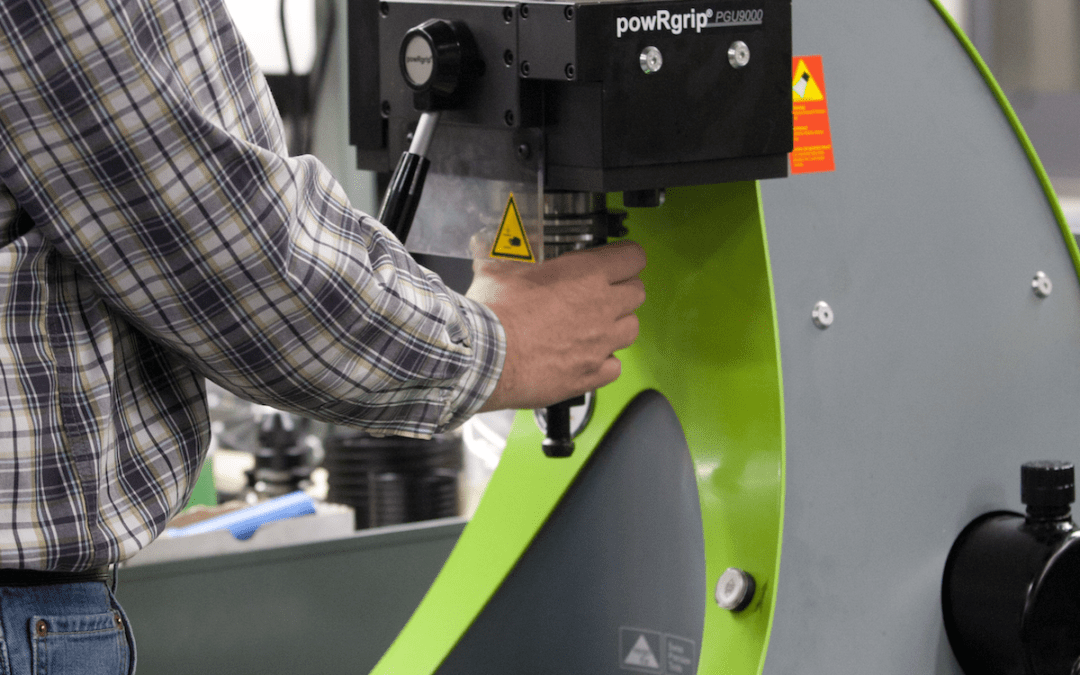

PowRgrip Series Makes Tool Holding a Big Deal

Aggressively machining with big, long cutters is nothing to take lightly when it comes to tool holding. Such conditions magnify the risk of cutter vibration, runout and pullout, which is why REGO-FIX went big with the latest addition to its industry-leading powRgip...

Aerospace OEMs Push to Automate Toolcribs

Automation continues to permeate the aerospace sector, and manufacturers in that industry implement it wherever possible. From machine tending to material handling, automation ensures process consistency, helps lower costs, speeds production and increases output....

powRgrip Takes Off in Aerospace

Whether aerospace manufacturers machine components for commercial, defense or space projects, they face a number of similar challenges. Reducing costs, getting the most from their tools, eliminating tool runout and pullout and shortening setup and cycle times are all...

Tolerances and Materials Generate Aerospace Manufacturing Headwinds

Higher complexity parts with tighter tolerances along with new and unique materials like composites (thermosets/thermoplastics), sandwiched/stacked materials and others continue to challenge aerospace manufacturers. As manufacturers incorporate advanced machining...

Making Sure Toolholders Stack Up for Long-reach Applications

Engineers continue to design increasingly, intricate and complex parts in an effort to combine multiple parts into one component, thus eliminating secondary assembly processes. In many cases, shops producing those parts are faced with long-reach machining applications...

Machining Memos isn’t just about REGO-FIX – it’s about what your shop needs to achieve manufacturing success, from how to handle runout and master high-speed machining to what things like blockchain technology or ergonomics have to do with your part-production operations.

Latest News:

REGO-FIX to Feature Toolholding System at SHOT WeekSM Suppliers Showcase

WHITESTOWN, Ind., January 9, 2025 – Before more than 55,000 hunters, outdoor enthusiasts and law enforcement officials arrive in Las Vegas to attend the annual SHOT Show in January, the event’s more than 2,500 exhibitors will have access to manufacturing partners...