The Real Value of an Ounce of Prevention

In our everyday lives, we’re encouraged not to “sweat the small stuff.” In shop life, however, that casual attitude can yield some expensive consequences if you apply it to your tools and toolholding. The moments you invest in keeping these items clean can help you...

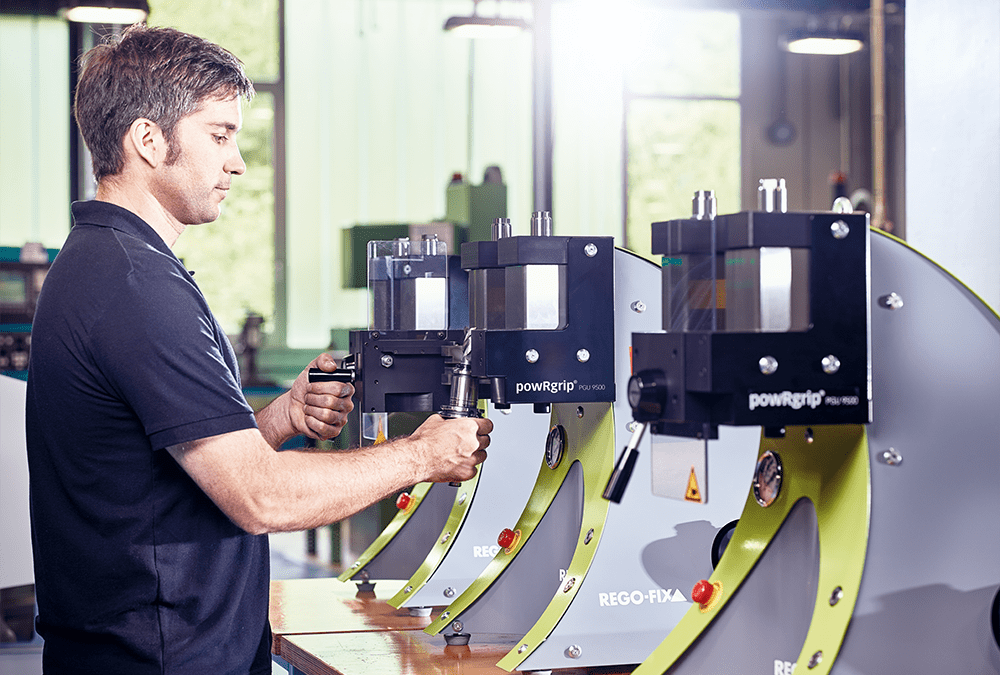

Training Ease with the REGO-FIX powRgrip® PGU 9500 Toolsetter

We love training customers on the powRgrip PGU 9500 toolsetting unit for two very simple reasons. First, we always want to help customers gain the fullest benefits from our technologies – and second, we truly enjoy seeing the looks on their faces when they realize how...

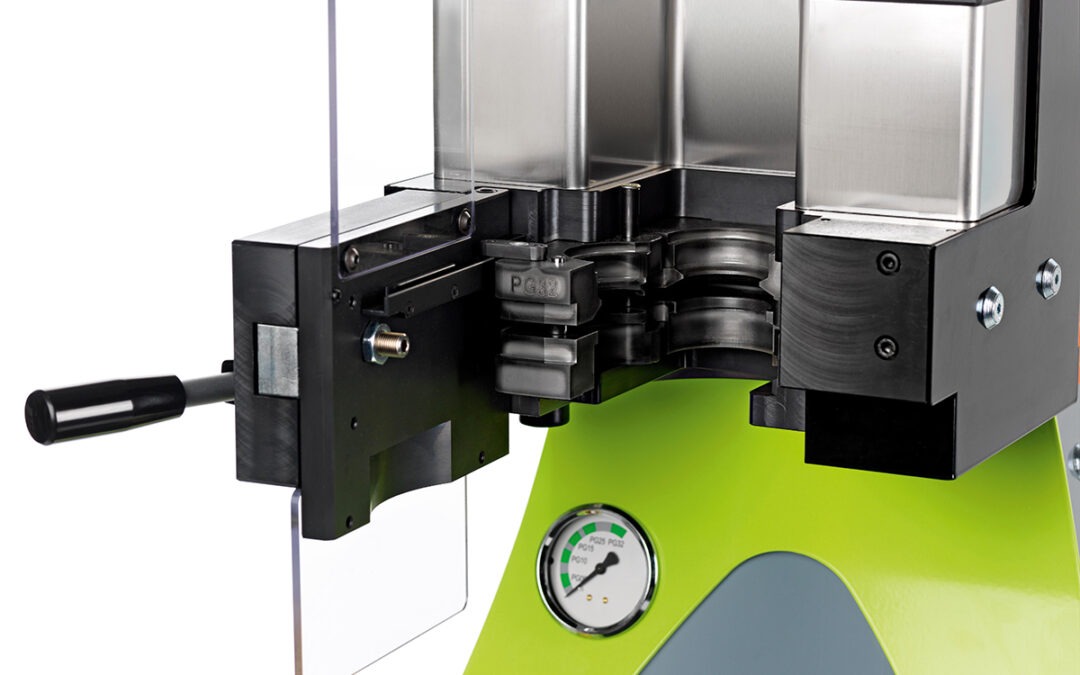

Why You Should Consider a powRgrip® Test and Trial for Your Shop

When you’ve spent as many years inventing and manufacturing high-quality toolholding as we have, you not only understand that manufacturers need precision, you’ve made it possible for them to meet that need. Beyond all our other options, we created the REGO-FIX...

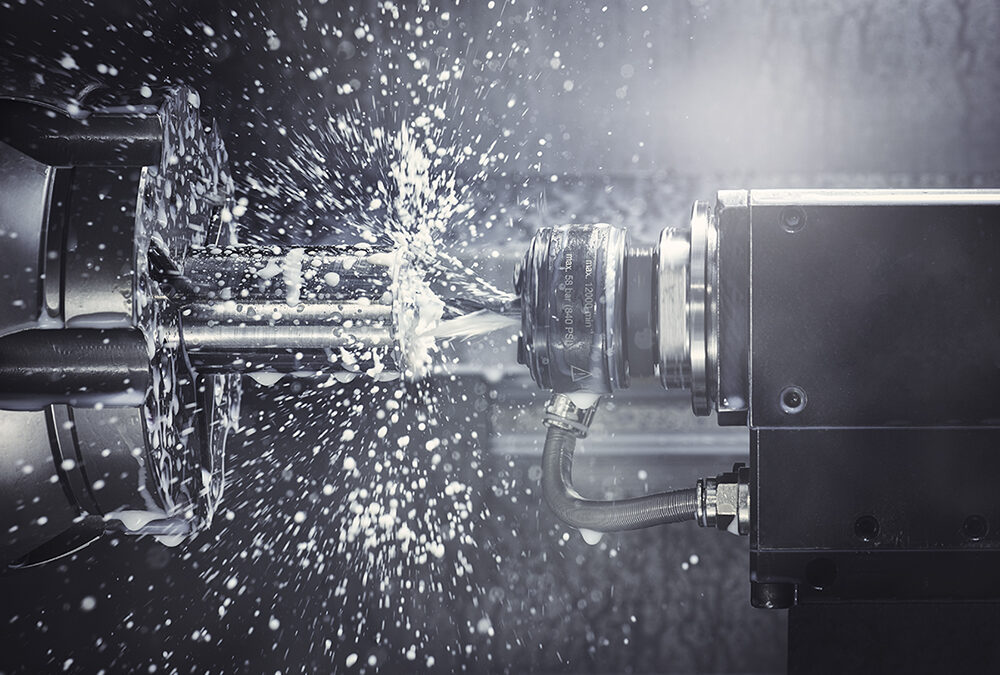

The Benefits of Perfectly Drilled Holes Start With Toolholding

Many manufacturers still consider drilling a very forgiving process that requires less precision on the part of toolholding. Realistically though, nothing could be further from the truth. Toolholding is the key to boosting drilling accuracy, which in turn, can improve...

The Pandemic and Automation Opportunities

Long before the pandemic upset the global labor environment, REGO-FIX was working on limiting human intervention in the production processes. There are some things you cannot automate, but you don’t need human interaction to swap a work piece from one machine to...

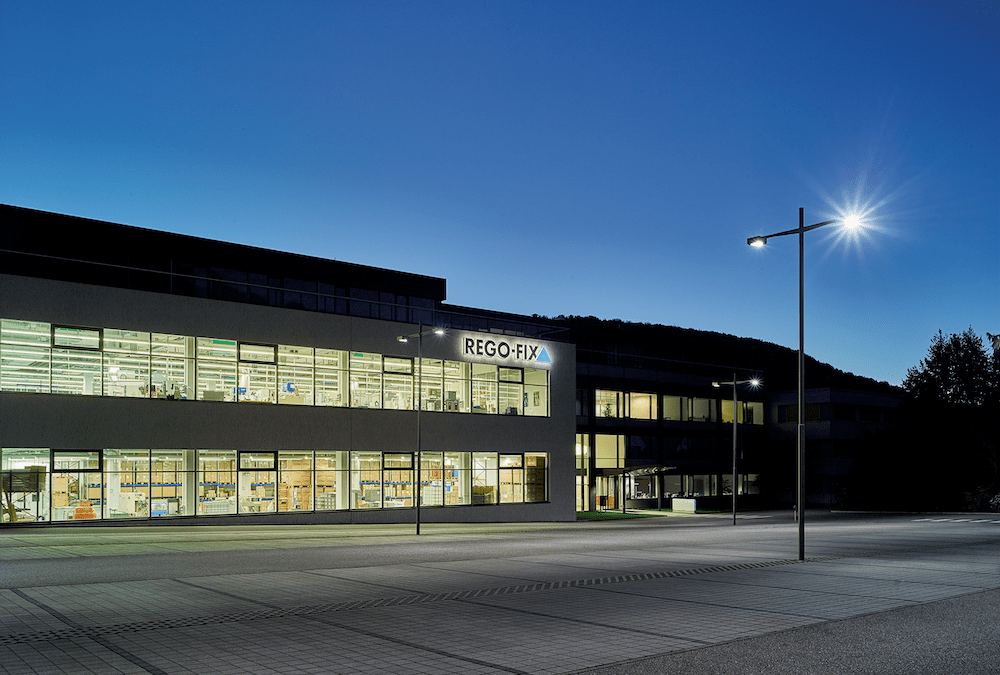

We Have What You Need When You Need It

REGO-FIX couldn't maintain its superb customer relationships without two essentials: the right toolholding to get the job done and the inventory availability to ensure that customers receive what they need when they need it. Large orders or small, we're always 100%...

What Quality Means to REGO-FIX

The essence of reliability is predictable, indisputable performance. In toolholding, that means never having to worry about product performance because you can depend on what you buy to deliver what you need. Quality is reputation, and REGO-FIX never stops striving to...

Temporary Disruptions, Long-Lasting Improvements

I believe that companies that have adapted best to the pandemic are also the ones who witnessed positive effects, and that REGO-FIX is among them. A main reason that REGO-FIX adapted quickly to COVID is that the Swiss government allowed companies to decide for...

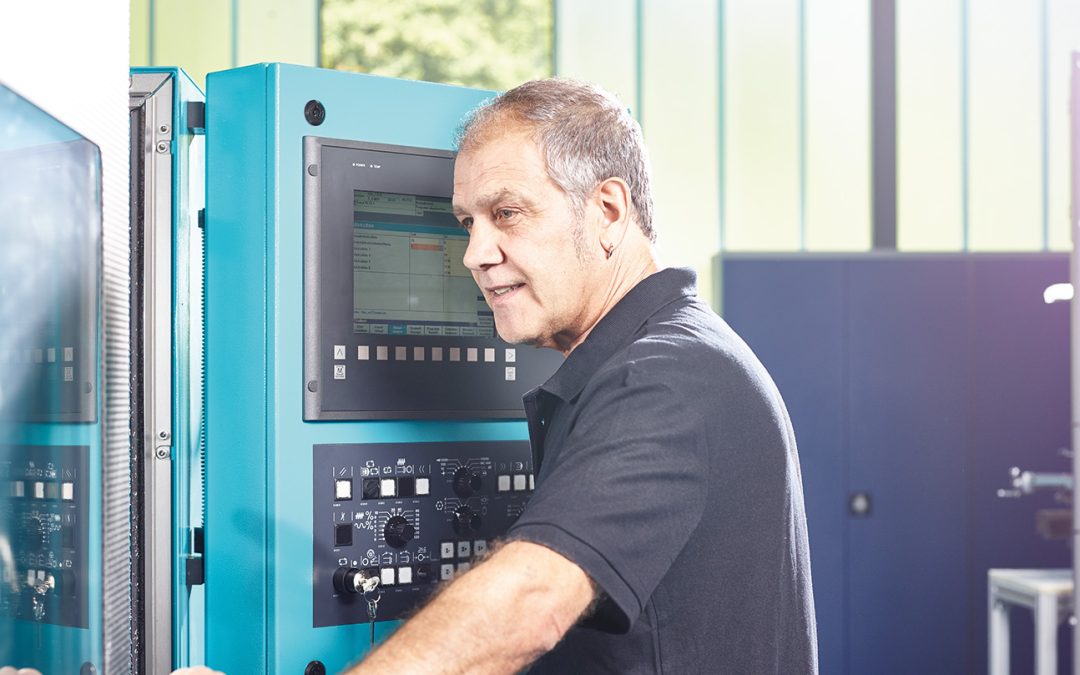

Sweat the Small Stuff to Avoid Big Problems

Our customers always want to take advantage of the full capabilities of their machine tools. They never want to use anything in a machine that can hamper its performance. That's why the two keys to proper toolholding – and machining results – are correct setup and...

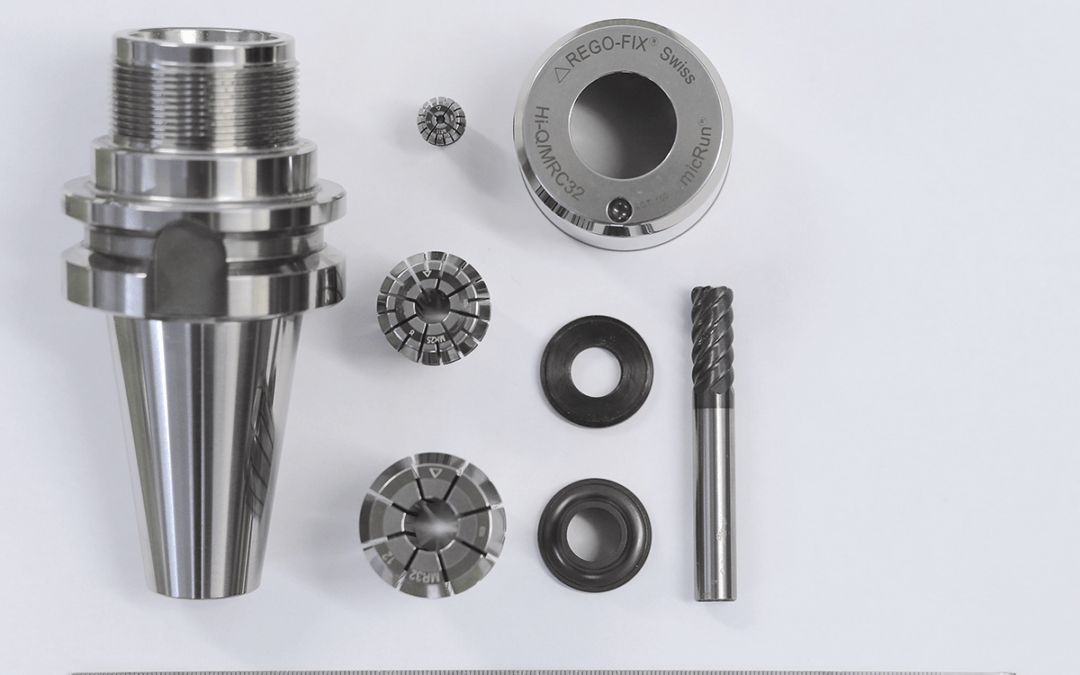

Stack Toolholding in Favor of Precision

Smaller components and tighter tolerances drive today's need for speed and precision, as tools get smaller, machines get faster and high-performance cutting is now the norm. Instead of making slow, deep passes across a part, today's machines use light cuts and fast...

Machining Memos isn’t just about REGO-FIX – it’s about what your shop needs to achieve manufacturing success, from how to handle runout and master high-speed machining to what things like blockchain technology or ergonomics have to do with your part-production operations.

Latest News:

REGO-FIX Elevates Customer Support with New National Sales Manager

whitestown, Ind., May 6, 2024 – REGO-FIX has announced the selection of Brent Broderick as the company’s new National Sales Manager. In addition to managing sales team members, Broderick will provide them ongoing technical education and guidance, ensuring that...