Holding on Tight: Toolholders as Workholders in Micro Machining

Miniaturization in manufacturing is becoming a clear trend. Whether in medical, automotive, aerospace or electronics, the demand on manufacturers to produce ever-smaller components continues to rise, while achieving accuracy on complex details that are smaller than a...

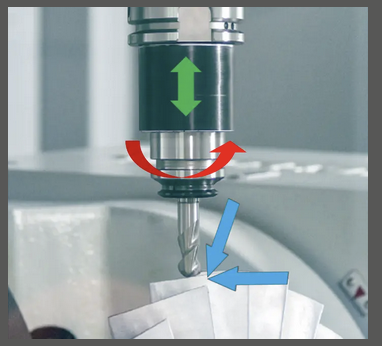

Extend Tool and Holder Life with powRgrip

Longer tool life equals lower production costs, but how do you lengthen tool lifespan? When you understand the factors that compromise tool performance, you can take steps to remove these obstacles from your production line – and optimize part quality along with...

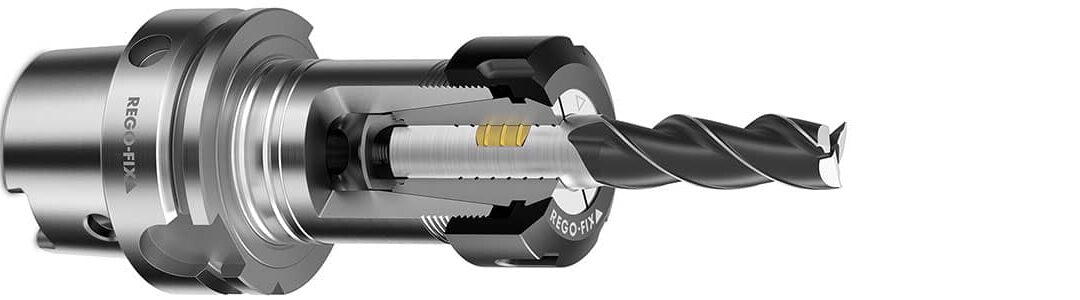

Get a Secure Grip On Tool Pullout Problems

Tough-to-machine materials and/or aggressive metal removal rates require equally tough and aggressive toolholding to prevent cutter pullout. It is for this reason that REGO-FIX developed the secuRgrip toolholding system that literally locks cutting tools in place for...

The Values Behind Corporate Culture and Customer Service

Earlier this year, REGO-FIX was recognized as one of Indiana’s top employers for the fourth consecutive year by the Indiana Chamber of Commerce. It was another round of high praise among strong competition that reinforces the significance of the REGO-FIX Triangle of...

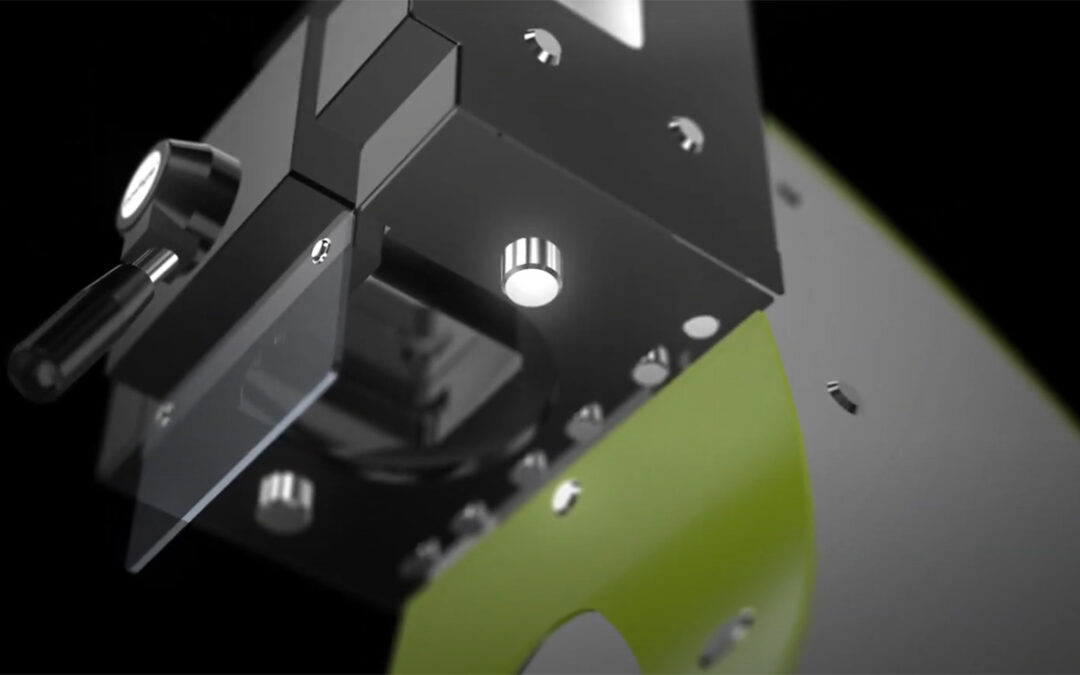

Smart Tooling Takes Autonomous Machining By Force

A REGO-FIX special guest blog featuring Pro-Micron From handwheel controls through punched-tape toolpath programming to full CNC guidance, machining operations have evolved from manual activities toward fully autonomous systems. Each step in the progression has made...

Tool Your Turrets In Minutes Rather Than Hours

Tool Your Turrets In Minutes Rather Than Hours It’s axiomatic that manufacturing machines only make money when they’re making chips, and the more chips machines produce by reducing setup and retooling downtime, the more money they make. While those statements apply...

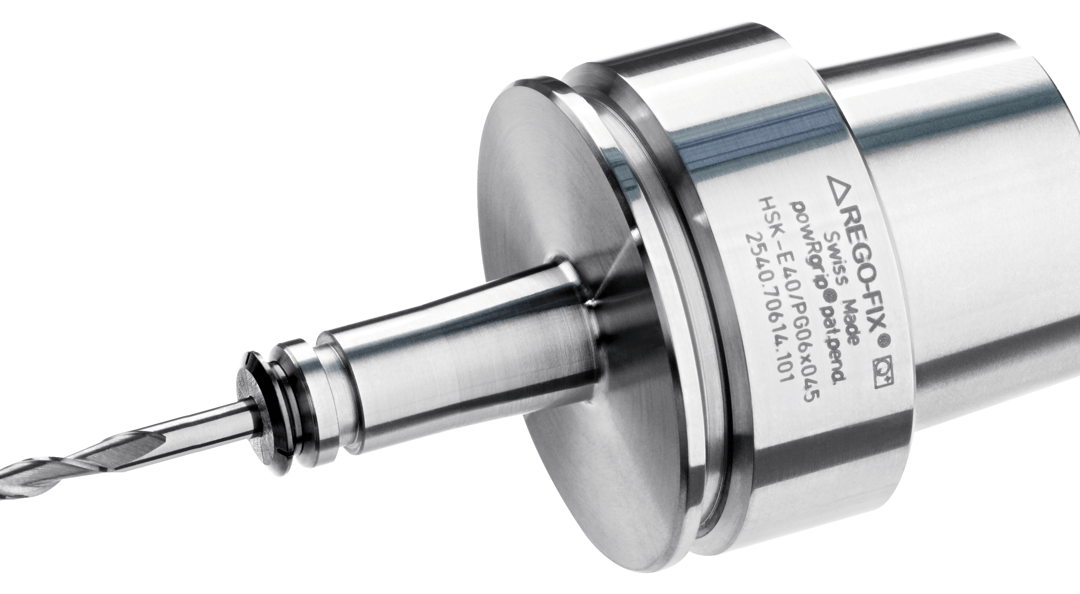

Cut the Corrosion with Stainless Tool Holders

Recent research and resulting innovations in the production of stainless steel tooling are enabling shops to meet the extreme cleanliness requirements of certain manufacturing sectors, especially those in the aerospace and medical industries. In those situations...

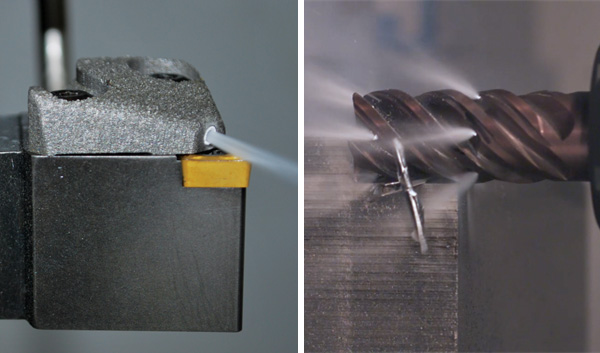

Through-tool Coolant Cuts Cycle Times

Many shops understandably try to recover the expensive acquisition cost of live-tool machines by saving on options that might seem unnecessary at the time of purchase. Through-tool, internal cooling is, in many cases, just such a machine feature shops might forego,...

Cool, Clean Cutting Coolant

Special REGO-FIX guest blog with Craig Happel, Vice President of Sales at Fusion Coolant Systems Liquid coolant is crucial in controlling the heat generated in metalcutting operations. Unfortunately, traditional coolant fluids contain additives that not...

Today’s RFID Technology Isn’t a Chip Off the Old Block

Radio-frequency identification (RFID) chip technology has saved many a production run simply by keeping track of and managing tools and toolholders. With the advent of Industry 3.0, toolholder embedded RFID technology expanded beyond what was essentially a license...

Machining Memos isn’t just about REGO-FIX – it’s about what your shop needs to achieve manufacturing success, from how to handle runout and master high-speed machining to what things like blockchain technology or ergonomics have to do with your part-production operations.

Latest News:

REGO-FIX Celebrates Innovation with Center for Machining Excellence Grand Opening

Whitestown, Ind., October 28, 2024– Swiss tooling company REGO-FIX welcomed attendees and manufacturing partners from across the globe for a day-long grand opening celebration of the company’s Center for Machining Excellence (CME). The event took place on October 24...