by David | Mar 31, 2022 | Blog

The essence of reliability is predictable, indisputable performance. In toolholding, that means never having to worry about product performance because you can depend on what you buy to deliver what you need. Quality is reputation, and REGO-FIX never stops striving to...

by David | Mar 7, 2022 | Blog

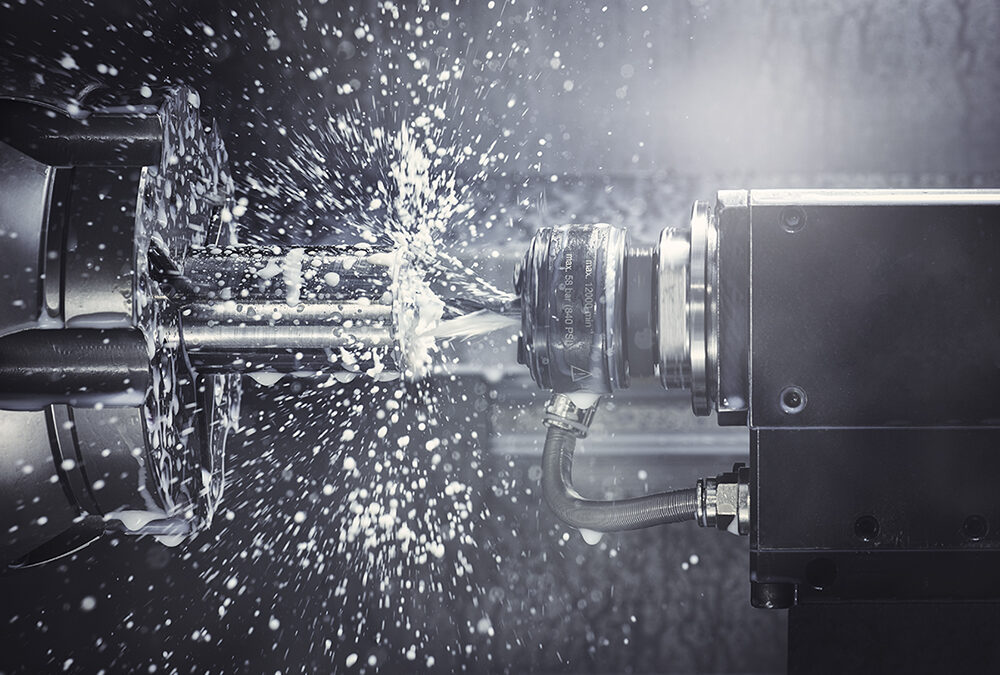

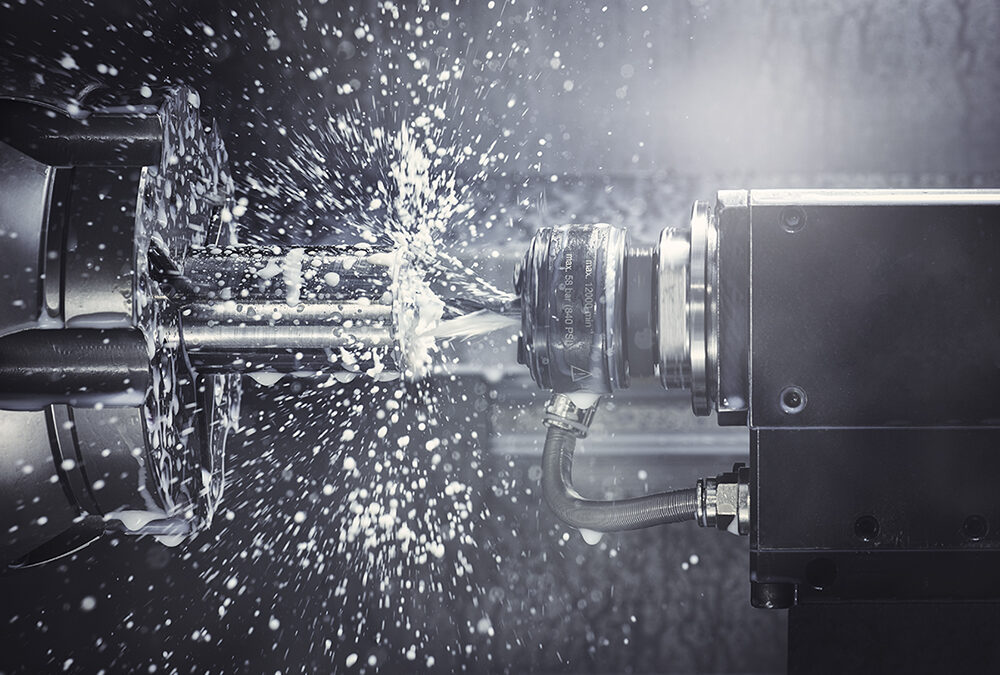

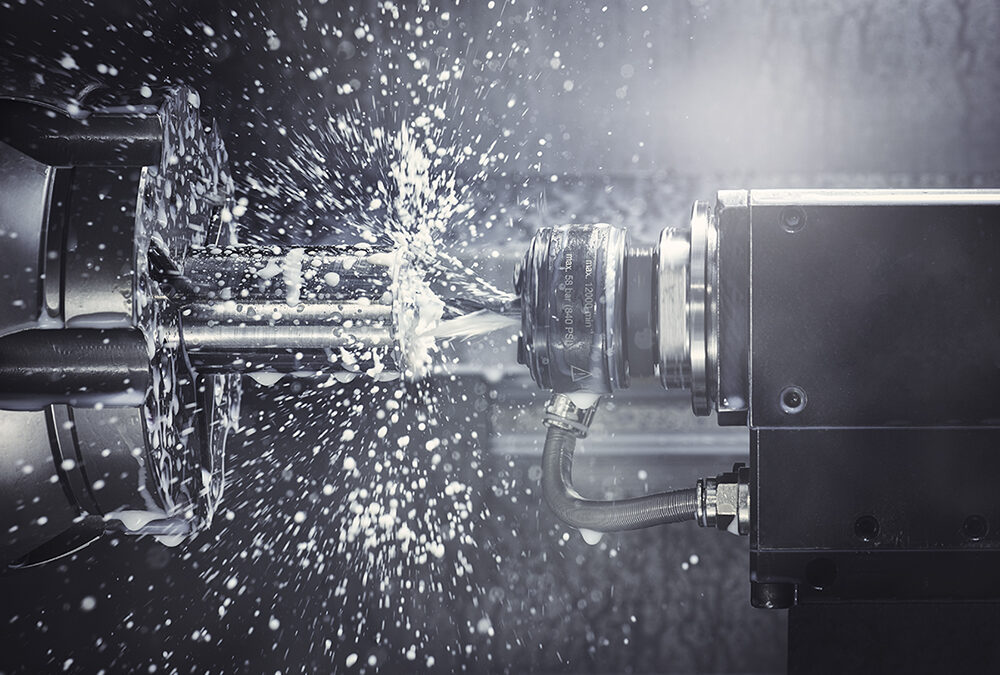

Our customers always want to take advantage of the full capabilities of their machine tools. They never want to use anything in a machine that can hamper its performance. That’s why the two keys to proper toolholding – and machining results – are correct setup...

by David | Nov 12, 2021 | Blog

If you’ve ever wondered why manufacturing uses a long list of spindle interfaces, the short answer is the continued improvement of the connection between toolholding and machine. Each interface includes its own unique advantages, and some target specific types...

by David | Sep 17, 2021 | Blog

Are you tightening your tools in an overtorqued death grip? If your notion of taper contact and pull stud torque dates back a few years, chances are that you’re deforming your tools and ramping up your runout. Time to catch up with today’s technology and...

by David | May 14, 2021 | Blog

Machine-tool runout stems from multiple causes, including fixturing, toolholders, cutting tools, machine tools themselves and unexpected intermittent sources. All these problems diminish surface finish, tool life and part tolerance. Finding the source of runout takes...