by REGO-FIX Team | Mar 7, 2023 | Blog

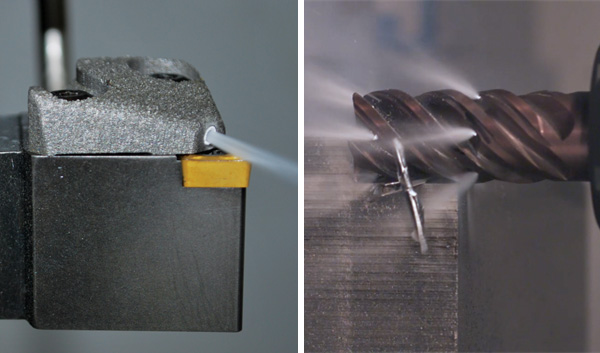

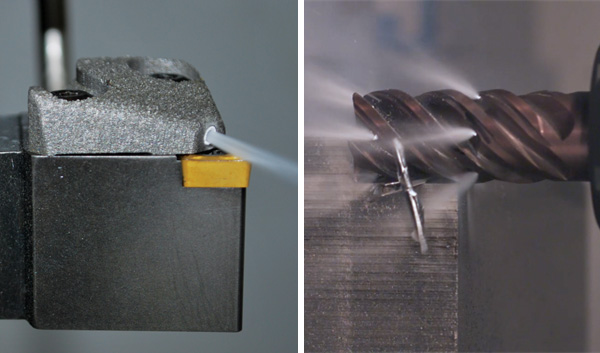

Many shops understandably try to recover the expensive acquisition cost of live-tool machines by saving on options that might seem unnecessary at the time of purchase. Through-tool, internal cooling is, in many cases, just such a machine feature shops might forego,...

by REGO-FIX Team | Feb 22, 2023 | News

WHITESTOWN, Ind., February 22, 2023 – REG0-FIX USA has named Carl D. Hynes, a 30-year veteran in manufacturing, distribution and sales, as the company’s new Northeast Territory Manager. Prior to joining REGO-FIX, Hynes served as sales manager and general...

by REGO-FIX Team | Feb 17, 2023 | News

WHITESTOWN, Ind., February 16, 2023 – REGO-FIX will feature high-precision toolholding especially suited for the demands of satellite, telescope, rocket and other sophisticated part production at SATELLITE 2023, one of the space and satellite sector’s...

by REGO-FIX Team | Feb 17, 2023 | News

WHITESTOWN, Ind., February 17, 2023 – In booth 5350, the REGO-FIX reCool® retrofittable coolant-through system and the company’s powRgrip tool holders will take center stage during EASTEC 2023. Both hugely popular in the manufacturing industry, reCool...

by REGO-FIX Team | Feb 14, 2023 | Blog

Special REGO-FIX guest blog with Craig Happel, Vice President of Sales at Fusion Coolant Systems Liquid coolant is crucial in controlling the heat generated in metalcutting operations. Unfortunately, traditional coolant fluids contain additives that not...