Find the right product for your needs

Our Mission

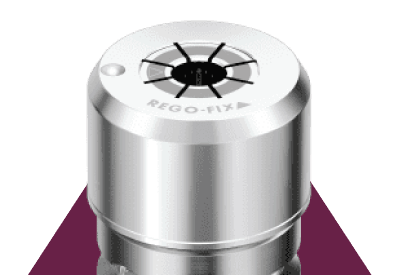

In every industry, with any type of material, part and quantity, REGO-FIX gives you the unmatched reliability you need for success. Our carefully matched systems provide optimal fit and accuracy to minimize vibration and tool runout while they maximize clamping force, toolholding security, tool life and output quality.

Our History

REGO-FIX introduced the first ER collet chuck in 1972, and it became the enduring industry standard. Today, our innovative solutions make it easy to achieve excellent surface finishes and consistent job results in a wide variety of machining applications. For the toolholding innovations you need to produce precise results every time, look to REGO-FIX.

Price & Availability Tool

Price and availability request for registered distributors.