We love training customers on the powRgrip PGU 9500 toolsetting unit for two very simple reasons. First, we always want to help customers gain the fullest benefits from our technologies – and second, we truly enjoy seeing the looks on their faces when they realize how incredibly easy this toolsetter is to operate. They’re expecting a training session that’s an hour or more of rocket science, and what we go through in about 10 or 15 minutes is about as complex as learning to use a microwave oven, if that.

One of the first lessons that operators and other customer personnel learn is that it’s very difficult to make a mistake using this unit, and even if you do, it’s equally easy to back up and correct the mistake you made. In some training sessions, we’ll demonstrate how to use the PGU unit, and then we’ll invite members of the group to come up and try using the device themselves.

After an initial moment of hesitancy – probably conditioned by the fact that many of the pieces of equipment on a production floor are completely unforgiving of mistakes – people “just get it,” and proceed to work their way through toolsetting procedures with confidence. As one person masters the device, they’ll call up a colleague to try using it, and very soon, a small group clusters around the machine while others line up, saying, “Hey, we want our turn.” The mood quickly changes from training session to something very much like fun.

It’s fun because it’s so easy, and ease catches people’s attention very quickly. Almost inevitably, someone in the group will come up to try using the unit, wearing a hesitant expression and looking at our trainer for reassurance. We’ll tell them, “Go ahead, try it for yourself.” In a matter of moments, that hesitancy is gone and the employee is using the device with confidence.

Managers often stand off to one side at first, just watching the session, and start to creep closer to the rest of the employees as they begin to see just how easy this really is. We often hear comments such as, “All we have to do is press a button?” or “I don’t see how we can make a mistake with this unit.” We tell them we’ve done everything in our power to make the PGU unit goofproof, to put all the complexities inside the machine so customers can make tool setup as quick and easy as it is precise. That’s a testament to the industrial design staff in our Switzerland global headquarters.

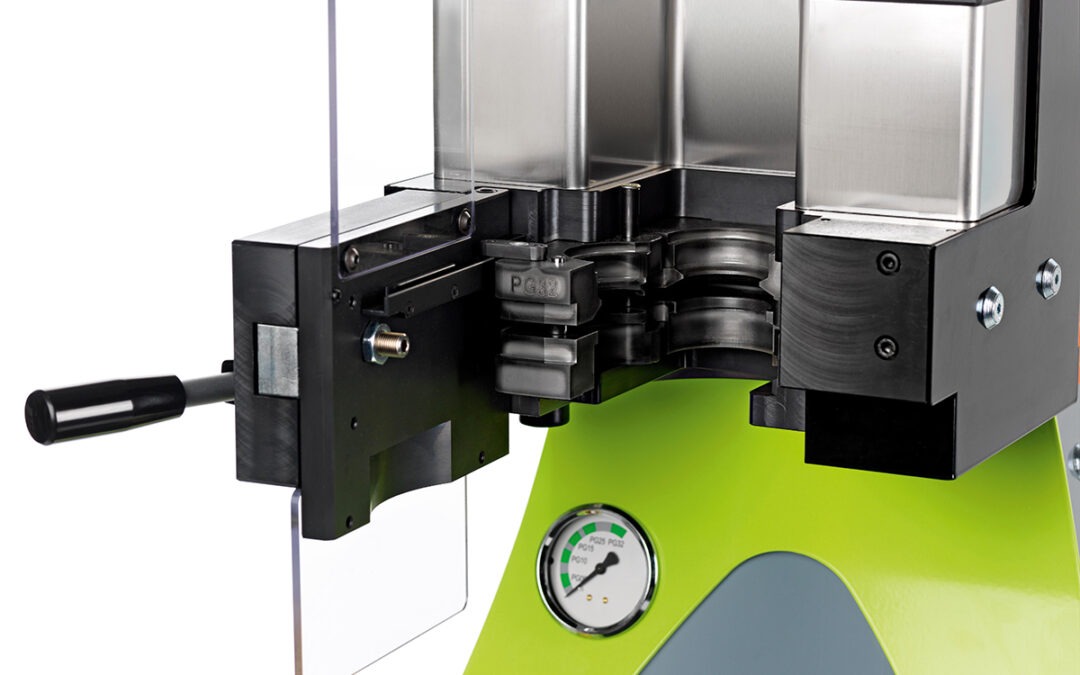

The PGU series toolsetters can press in a tool in under 10 seconds with up to 9 tons of force. These units can handle tapers including CAT, HSK, BT, CAPTO, BIG +, TC and ISO, all with high vibration damping and tool security. Take proper care of the PG system components, and their TIR won’t exceed 0.0001″ during our 5-year/20,000-cycle warranty. No heat, no mess, no complicated procedures, no lengthy cooldown before you can use your tools. Just repeatable precision and uncomplicated ease.

Along with our automated toolsetter, we also make the manually operated PGC 2506, which uses a hand pump instead of a powered system. If your shop processes only a few tool setups each day, the PGC unit provides just as much accuracy in a little more time. Either way, powRgrip offers you easy-to-use toolsetting that’s as accurate as it is simple to operate.